Van Điều Khiển Áp Suất UV 3.0,UV 3.0 Mankenber Viet Nam

Model: UV 3.0

Hãng: MANKENBERG

Kết nối DN: 15-50

Kết nối G: 1/2 - 2

Áp suất danh nghĩa PN: 1

Áp suất đầu vào: 0,002 - 0,52 bar

Kvs-value: 0,2 - 3,6 m³ / h

Nhiệt độ: 130 ° C

Hotline: 0933.911.903

Mail: thietbicongnghiepltt@gmail.com

Liên hệ với chúng tôi để có thêm thông tin và giá tốt nhất!

PRESSURE CONTROL

Back pressure regulators UV 3.0

Millibar control valve

Technical data

Connection DN 15 - 50

Connection G 1/2 - 2

Nominal pressure PN 1

Inlet pressure 0.002 - 0.52 bar

Kvs-value 0.2 - 3.6 m³/h

Temperature 130 °C

Medium liquids and gases

*RT = -10 °C up to + 50 °C

Description

Self-acting back pressure regulators are simple control valves offering accurate control while being easy to install and maintain. They control the pressure upstream of the valve without requiring pneumatic or electrical control

elements.

The UV 3.0 backpressure regulator is a diaphragm-controlled spring-loaded

proportional control valve for very small outlet pressures and medium volumes. This backpressure regulator is manufactured from deep-drawn stainless steel featuring excellent corrosion resistance.The valve cone is fitted

with a soft seal.

The inlet pressure to be controlled is balanced across the valve seat by the

force of the valve spring (set pressure). If the inlet pressure rises above the

set pressure, the valve opens. With decreasing inlet pressure the valve control orifice reduces. When the pipeline is depressurised, the valve is closed.

Rotating the adjusting screw clockwise increases the inlet pressure.

The valve requires a sense line (to be installed on-site).

These valves are no shut-off elements ensuring a tight closing of the valve.

In accordance with DIN EN 60534-4 and/or ANSI FCI 70-2 they may feature

a leakage rate in closed position in compliance with the leakage classes V.

Standard

» All stainless steel construction

» Sense line connection

Options

» pressure gauge connection

» for toxic or hazardous media: sealed bonnet complete with leakage line

connection (incl. sealed adjusting screw). Must be installed with a leakage line capable of draining leaking medium safely and without pressure

» various diaphragm and seal materials suitable for your medium

» special connections: Aseptic, ANSI or JIS flanges, NPT, welding spigots;

other connections on request

» special versions on request

Technical specification

| K vs values [m3/h] for all body sizes | |||||

| 0.2 | 0.9 | 1.5 | 2.2 | 2.8 | 3.6 |

| Setting ranges [bar] | diaphragm [mm] | ||

| 0.002 - 0.004 | 0.003 - 0.015 | ø 500 | |

| 0.004 - 0.010 | 0.005 - 0.032 | ø 360 | |

| 0.008 - 0.016 | 0.015 - 0.065 | 0.05 - 0.28 | ø 270 |

| 0.015 - 0.03 | 0.025 - 0.125 | 0.1 - 0.52 | ø 220 |

| Materials | ||

| Temperature | 80 °C | 130 °C |

| Body, Bonnet, Internals, Screws | Stainless steel | Stainless steel |

| Set screw | Stainless steel M10 with handwheel made of Duro plast | |

| Spring | Stainless steel | Stainless steel |

| Valve seal | FKM | FKM |

| Diaphragm | NBR | EPDM |

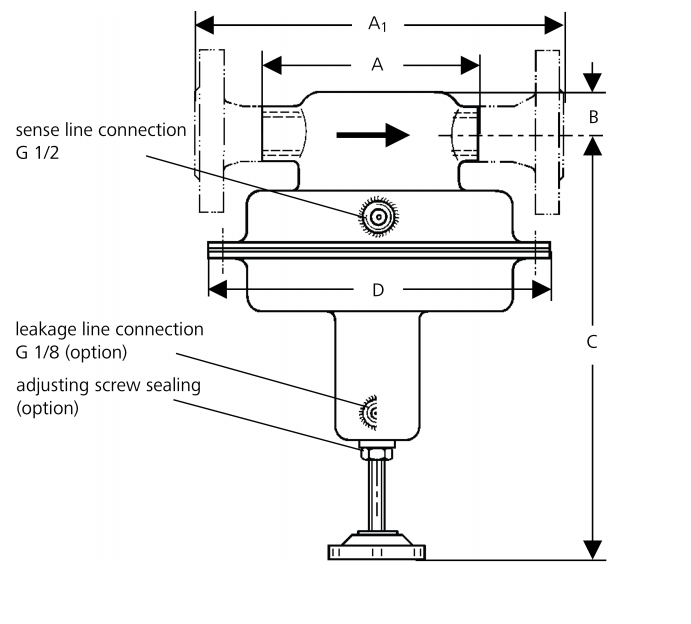

| Dimensions [mm] | ||||||

| Size | nominal diamete DN | |||||

| 15 | 20 | 25 | 32 | 40 | 50 | |

| A* | 165 | 170 | 170 | 180 | 180 | 180 |

| B | 35 | 35 | 35 | 40 | 45 | 50 |

| C | 320 | 330 | 330 | 340 | 350 | 360 |

| D | diaphragm diameter see table setting ranges |

| Dimensions [mm] | ||||||

| Size | nominal diameter G | |||||

| 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | |

| A1* | 240 | 240 | 250 | 250 | 260 | 260 |

| B | 35 | 35 | 35 | 40 | 45 | 50 |

| C | 320 | 330 | 330 | 340 | 350 | 360 |

| D | diaphragm diameter see table setting ranges |

*overall length tolerances in acc. with DIN EN 558

| Weights [kg] | |||

| Diaphragm diameter mm | nominal diameter | ||

| G 1/2 - 2 | DN 15 - 25 | DN 32 - 50 | |

| ø 500 | 13 | 15 | 17 |

| ø 360 | 12.5 | 14.5 | 16.5 |

| ø 270 | 8 | 10 | 12 |

| ø 220 | 6 | 8 | 10 |

| Customs tariff number |

| 84814010 |

Không có nhận xét nào:

Đăng nhận xét