VSM (UV 4.4) Van Điều Khiển Áp Suất VSM (UV 4.4), Mankenber Viet Nam

Model: VSM (UV 4.4)

Hãng: MANKENBERG

Kết nối DN: 50 - 150

Áp suất danh nghĩa PN: 10, 16, 25, 40

Áp suất đầu vào: 1,5 - 6 bar, 5 - 12 bar

Kvs-Value: 20 - 190 m³/h

Nhiệt độ: 70°C

Hotline: 0933.911.903

Mail: thietbicongnghiepltt@gmail.com

Liên hệ với chúng tôi để có thêm thông tin và giá tốt nhất!

Pressure Control Valves

Back Pressure Regulators VSM (UV 4.4)

Epoxy-coated Cast Valve for medium Flow Rates

Technical Data

Connection DN 50 - 150

Nominal Pressure PN 10, 16, 25, 40

Inlet Pressure 1.5 - 6 bar, 5 - 12 bar

Kvs-Value 20 - 190 m³/h

Temperature 70 °C

Medium water

Description

Self-acting back pressure regulators are simple control valves offering

accurate control while being easy to install and maintain. They control

the pressure upstream of the valve without requiring pneumatic or

electrical control elements.

The VSM (UV 4.4) backpressure regulator is a piston-controlled,

spring-loaded proportional regulator with relief for large throughputs.

The valve housing is made of spheroidal graphite iron with a continuous

epoxy coating while the valve cone is soft-sealed.

The inlet pressure to be controlled is balanced across the valve seat by

the force of the valve spring (set pressure). If the inlet pressure rises

above the set pressure, the valve opens. With decreasing inlet pressure

the valve control orifice reduces, when the pipeline is depressurised, the

valve is closed. Rotating the adjusting screw clockwise increases the inlet

pressure.

These valves are no shut-off elements ensuring a tight closing of the

valve. In accordance with DIN EN 60534-4 and/or ANSI FCI 70-2 they

may feature a leakage rate in closed position in compliance with the

leakage classes V.

Standard

» Designed acc. to EN-1074/4

» Flanges as per EN 1092/2

» Pressure stage PN 16

» Body made of spheroidal cast iron GJS 450-10 with epoxy coating in

blue RAL 5005, thickness min. 250 μm

» Internal parts made of stainless steel 1.4301

» Closed spring cap

» Internal control bore

» Coating as per DVGW W270 and KTW recommendation of the

German Ministry for Health

» Pressure gauge pre-installed

Options

» Internal parts made of 1.4404

» Elastomers made of EPDM or Viton

» Pressure stages PN 25 and PN 40

» Special designs on request:

- Nickel-plated version for air and liquids up to 100°C,

elastomers made of Viton

- Flanges drilled in acc. with ANSI

Operating instructions, know how and safety instructions must be

observed. The pressure has always been indicated as overpressure.

We reserve the right to alter technical specifications without notice.

| Kvs-Values [m³/h] | |||||

| nominal diameter DN | |||||

| 50 | 65 | 80 | 100 | 125 | 150 |

| 20 | 50 | 80 | 120 | 165 | 190 |

| Setting Ranges [bar], Nominal Pressure PN | ||

| bar | 1.5 - 6 | 5 - 12 |

Upstream Pressure Buildup

The plot is showing the increase in the upstream pressure that occurs

through the valve, when the flow increases. Ensure that the operating

conditions fall on the area depicted in blue for the recommended fluid

flow velocity through the valve.

| Materials | |

| Body | spheroidal cast iron GJS 450-10 epoxy coated* |

| Spring Cap | spheroidal cast iron GJS 450-10 epoxy coated* |

| Spring | stainless steel 55SiCr6 |

| Internals | stainless steel 1.4301 |

| Valve Seal | NBR optional EPDM or Viton |

| O-ring (balance) | NBR optional EPDM or Viton |

* in accordance with KTW-recommendation and DVGW W270, thickness

min. 250 μm

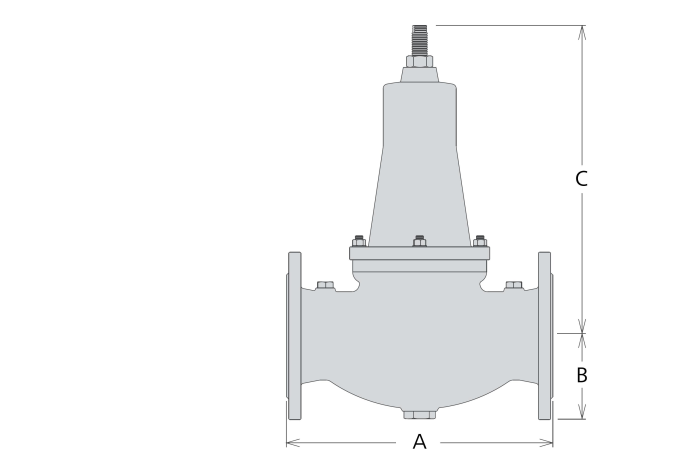

| Dimensions [mm] | ||||||

| size | nominal diameter DN | |||||

| 50 | 65 | 80 | 100 | 125 | 150 | |

| A | 230 | 290 | 310 | 350 | 400 | 450 |

| B | 83 | 93 | 100 | 117 | 135 | 150 |

| C | 280 | 320 | 350 | 420 | 590 | 690 |

| Weights [kg] | |||||

| nominal diameter DN | |||||

| 50 | 65 | 80 | 100 | 125 | 150 |

| 12 | 19 | 24 | 34 | 56 | 74 |

| Customs Tariff Number |

| 84814010 |

.PNG)

Không có nhận xét nào:

Đăng nhận xét