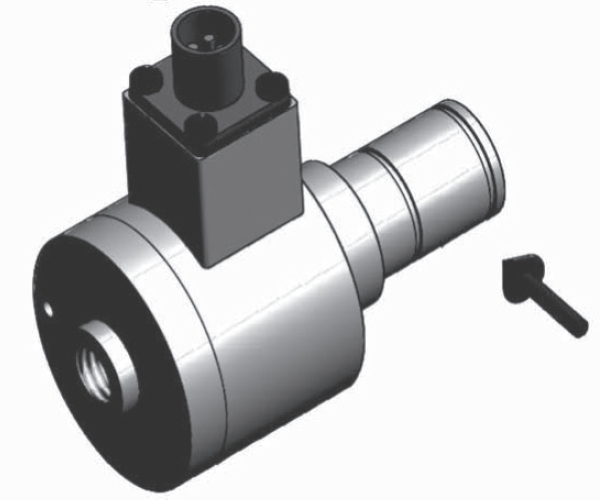

Cảm biến lực Gicam R44

- Model: GICAM R44

- Hãng: Gicam

Cảm Biến Lực Trục Quay

Dãi đo: 100, 250, 500, 750, 1000 N

Ngõ ra: 1 mV/V

Nguồn cấp: Vcc 18 Max

Hotline: 0933.911.903 (Ms.Nhi)

Mail: thietbicongnghiepltt@gmail.com

Liên hệ với chúng tôi để có thêm thông tin và giá tốt nhất!

Cảm biến lực Gicam, Cảm biến lực dạng mặt bích

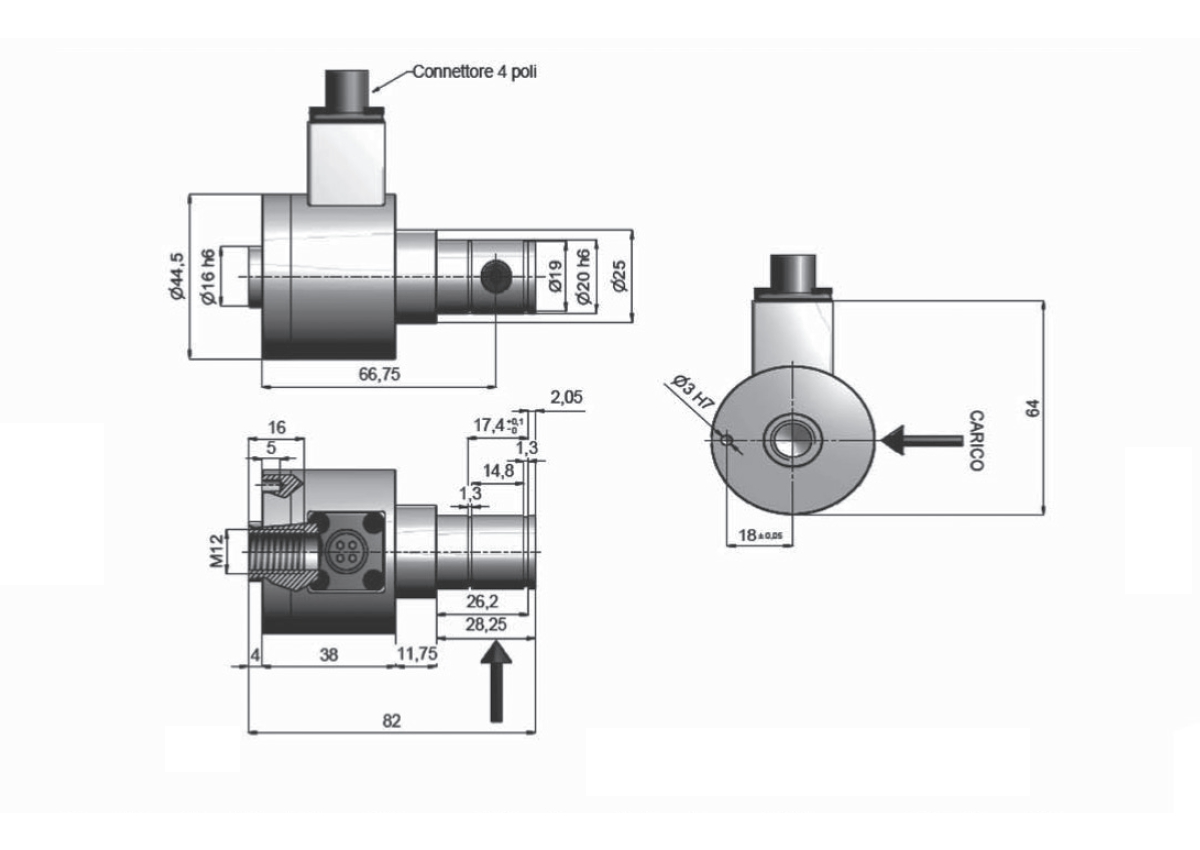

Features: Compact, excellent resolution. Easy to assemble. Orientable by M12 holes. Minimal deformation Protection against overloads.

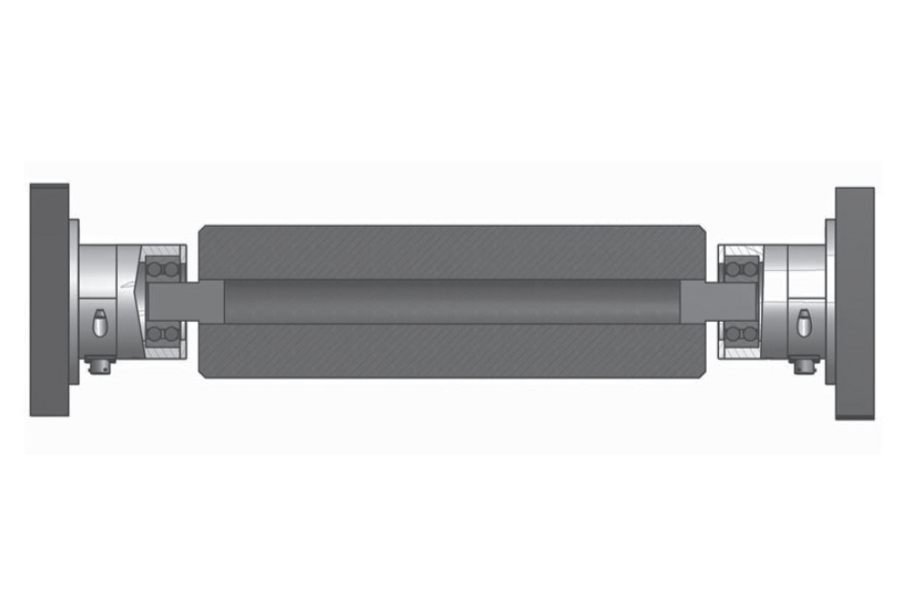

Applications: for the measure of tension tapes, paper, nylon, rubber, metallic laminated, tessil, flexographic printing presses etc.

Click to enlarge image

Technical Specifications

| Material | Steel |

| Nominal load | 100, 250, 500, 750, 1000 N |

| Limit load | 400 % F.S. |

| Breaking load | 500 % F.S. |

| Nominal load deflection | 0,08 mm |

| Supply voltage | Maximum 18 V dc |

| Sensitivity | 1 mV/V |

| Output tollerance | 0,1 % F.S. |

| Zero tollerance | 0,5 % F.S. |

| Linearity | 0,1% F.S. |

| Hysteresis | 0,03 % F.S. |

| Reapeatability | 0,1 % F.S. |

| Input resistance | 350-360 ohm |

| Output resistance | 350-353 ohm |

| Insulation resistance | >= 2000 Mohm |

| Creep (30 Minutes) | 0,03 % F.S. |

| Thermal compensation | -10 / +40°C (14 / +104°F) |

| Operating temperature | -20 / +70°C (-4 / +158°F) |

| Temperature deviation zero | 0,003 % F.S. / °C |

| Temperature deviation full scale | 0,002 % F.S. / °C |

| Protection class | IP 54 |

| Connection | Panel male connector UTS08E4P |

| Standard cable length | Loose female connector UTS6JC8E4S, connection cable 4 x 0,25 (length to be defined) |

Download PDF

Connections

| Type | CONNECTOR M8 RSMF 4/0.5M |

| Length | 5 m (body lead cell not connected shield) |

| Pin 1 | + IN |

| Pin 2 | - OUT |

| Pin 3 | - IN |

| Pin 4 | + OUT |

MOUNTING OF THE LOAD CELL

General precautions to be followed in the installation and assembly of load cells:

- Follow the direction of application of force on the load cell

- Do not exceed the limits of the temperature as indicated in the data sheet

- Do not remove labels from the load cell

- Adequately protect the cables with sleeves or channels

- Carry out on each load cell a ground connection with suitable cable, shunt on mounting accessories

- Do not carry out any welding on the mechanical structure after mounting the load cell

- Avoid or reduce to a minimum level any mechanical constraints between the rigid structure and the weighing structure to avoid error in weighing and return to zero

- In case of vibration or dynamic loads product the load cells with puffers / shock absorbers

- Protect load cell from any dust accumulation with any appropriate means

Không có nhận xét nào:

Đăng nhận xét