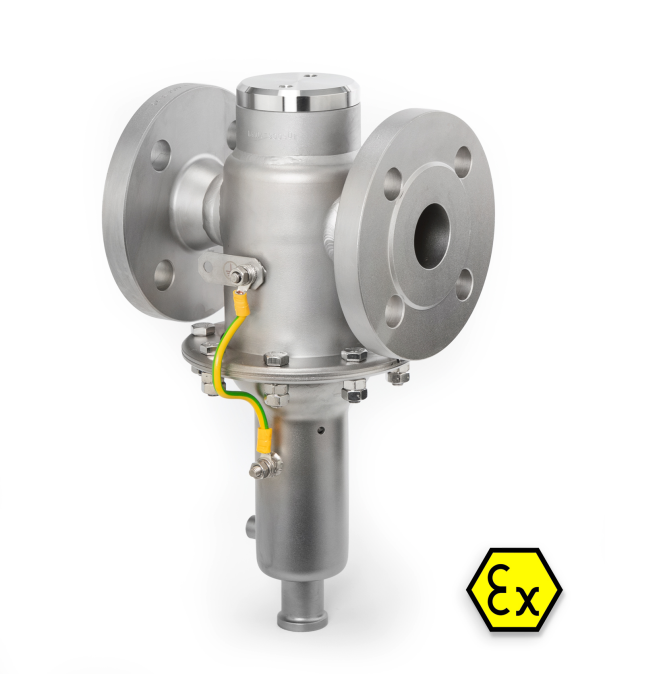

DM 652 ATEX H2 Van Giảm Áp DM 652 ATEX H2 Mankenber, Mankenber Viet Nam

Model: Valve DM 652 ATEX H2

Hãng: MANKENBERG

Kết nối DN: 15-50

Kết nối G: 1/2 - 2

Áp suất đầu vào: 40 bar

Áp suất đầu ra: 0,1 - 12 bar

Kvs value: 5 - 22 m³ / h

Nhiệt độ: -10 ° C lên đến 130 ° C

Hotline: 0933.911.903

Liên hệ với chúng tôi để có thêm thông tin và giá tốt nhất!

Pressure control valves

Pressure reducing valves DM 652 ATEX H2

for medium to large flow rates, especially for hydrogen applications

Technical Data

Connection DN 15 - 50

Connection G 1/2 - 2

Nominal pressure PN 40

Inlet pressure 40 bar

Outlet pressure 0,1 - 12 bar

Kvs value 5 - 22 m³/h

Temperature -10 °C up to 130 °C

Medium liquids, gases, hydrogen

Description

Self-acting pressure reducers are simple control valves offering accurate

control while being easy to install and maintain. They control the

pressure downstream of the valve without requiring pneumatic or

electrical control elements.

The pressure reducing valve DM 652 ATEX H2 was specially developed

for hydrogen applications. It is a diaphragm-controlled, spring-loaded

and balanced proportional control valve for medium to large flow rates.

The valve is completely made of high-quality stainless steel with excellent

corrosion resistance. Since the body and the bonnet are manufactured

by the deep-drawing process, the valve is very lightweight and compact.

The valve cone is soft-sealed.

The outlet pressure to be controlled is balanced across the control unit

by the force of the valve spring (set pressure). As the outlet pressure rises

above the pressure set using the adjusting screw, the valve cone moves

towards the seat and the volume of medium is reduced. As the outlet

pressure drops, the valve control orifice increases; when the pipeline is

depressurised, the valve is open. Rotating the adjusting screw clockwise

increases the outlet pressure.

The valves requires a sense line (to be installed on-site).

These valves are no shut-off elements ensuring a tight closing of the

valve. In accordance with DIN EN 60534-4 and/or ANSI FCI 70-2 they

may feature a leakage rate in closed position in compliance with the

leakage classes V optional IV.

Standard

» All stainless steel construction

» Non rising adjusting screw

» Sense line connection

» Balanced cone for controlling the outlet pressure indipendently from

the initial pressure

Special features of the ATEX version

» Conformity to ATEX Directive 2014/34/EU and DIN EN ISO 80079-36

» Leakage line connection, adjusting screw seal and lock

» Potential equalization among the valve components

» Grounding device at the valve body

» Secured body connections with collar flange

» Electrically conductive components

» Piston made of low-spark material

» Additional venting hole in the spring cap

Options

» Various diaphragm and seal materials suitable for your medium

» Special connections: Aseptic, ANSI or JIS flanges, NPT, welding spigots;

other connections on request

Operating instructions, supplementary operating instructions, know-how

and safety instructions must be strictly observed. All the pressure has

been specified as overpressure. Technical data subject to change.

| ATEX Marking |

| Ex II 2G Ex h IIB+H2 85 °C ... 155 °C Gb X |

| Kvs-values [m3/h] | |||||||

| nominal diameter | G | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 |

| DN | 15 | 20 | 25 | 32 | 40 | 50 | |

| Kvs-value | m3/h | 5 | 7 | 8 | 22 | 22 | 22 |

| Setting Ranges [bar], Nominal Pressure | ||

| 0.1-0.5 | 0.3-1.1 | 0.8-2.5 |

| PN 16-40/1 | PN 16-40/2,5 | PN 16-40/6 |

| Setting Ranges [bar], Nominal Pressure | ||

| 2 - 5 | 4 - 8 | 6 - 12 |

| PN 16-40/10 | PN 16-40/16 | PN 16-40/16 |

| Permissible Reduction Ratio (max. p1/p2) | ||

| setting range bar | nominal diameter | |

| G 1/2 - 1 | G 1 1/4 - 2 | |

| DN 15 - 25 | DN 32 - 50 | |

| 0.1 - 0.5 | 40 | 25 |

| 0.3 - 1.1 | 30 | 18 |

| 0.8 - 12 | 20 | 12 |

Không có nhận xét nào:

Đăng nhận xét